Producing cannabis edibles production means cannabis compliance and food production regulations and oversight.

In a matter of decades, cannabis edibles transformed from a countertop hobby into a multibillion-dollar industry. With this radical blossoming comes a new crop of technology needed to stay competitive in the ever-growing cannabis industry and to supply the types of edibles at cannabis dispensaries.

While states with legal cannabis have set a precedent, the FDA has yet to define clear regulations. Thus, this creates large vulnerabilities in the industry, putting undue liability on the producer rather than easily understood legislation. Until the FDA takes action to sort out the industry’s rules, producers will have to fend for themselves in this often-unwieldy environment.

Using the right equipment is the first step to meeting the rigorous demands of commercial cannabis food production.

HOW CAN ONE ACHIEVE INDUSTRIAL CONSISTENCY?

The baked goods and gummies available in supermarkets today are far from handmade. Commercial food production uses large industrial equipment and processes. Equipment such as molders and de-molders are an integral part of the process that allows for uniform and consistent products.

These devices are almost self-explanatory in that they load and unload edibles from molds. Not only does this help with eye appeal in addition to a reputation for a uniform product, but it helps ensure food-safe quality. Other pieces of machinery are used to rack and de-rack molds for ease of cooking and general processing.

While automation is a tempting option, it’s not always necessary, even with industrial equipment. The right tool at the proper scale can be adequate even for large-scale production.

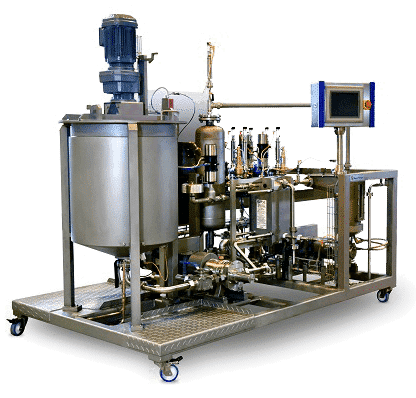

Now that cannabis graduated into a daytime industry, such equipment is a mainstay in the production of edibles. Before getting to molding, the edibles must be produced in food-safe environments and homogenized. Continuous cookers are an option to produce a consistent and usable product. These machines create a cannabis syrup that dispenses in a variety of ways.

While it’s up to the producer to decide how to apply these syrups, tanks, and other pieces of machinery, keep all of the ingredients moving, making sure they bond properly. Keeping a mixer running makes sure that material doesn’t clump or become heterogeneous, thus ruining the consistency of a batch. Through using such machines, edibles are more consistent and appropriately dosed.

CHOOSING THE RIGHT EXTRACT FOR THE JOB

Rosin presses allow for a solventless method for clean cannabis edibles. While rosin presses may have been in the niche market before, rosin equipment is scaling up to the industrial scale. This full-spectrum and solventless extraction method could become the standard for health-conscious consumers.

Additionally, using rosin for edibles allows for a full-spectrum experience. This extraction method keeps the terpenes and flavonoids in the extract, allowing for a more potent product.

Other options include nano-emulsions, which have the benefit of being water-soluble. Through different strategies like sonication, machines convert cannabinoids into water-soluble compounds, which can easily be added to products. One of the best applications is beverages, as the cannabinoids would already be bioavailable and subtle within the product. However, these soluble cannabinoids are also an excellent, flavorless option for edibles, although oil-soluble edibles tend to be more common within the industry.

Proponents of water-soluble cannabinoids highlight the increased accuracy of dosing. This accuracy is because water-soluble compounds don’t need to be converted into something usable by the body by the digestive system.

Using these emulsions meant settling for isolated cannabinoids or cannabinoid formulations until recently. In a recent interview with Cannabis Tech, the father-daughter team behind NXTLVL discussed their proprietary process using micelle technology to encapsulate the full spectrum of compounds provided by the plant.

HOMOGENEITY AND THE EQUIPMENT REQUIRED

Homogenizers are tools that make particles uniform. A high-pressure homogenizer is ideal for those who wish to make ultrafine particles. It uses force to split the particles down into smaller pieces. Otherwise, all homogenizers pump particles through small openings to a targeted size.

For cannabis product manufacturing, this tool cannot be underrated. Manufacturers can add properly processed cannabinoids to nearly any product. Homogeneity allows for superior storage and thus available application. It can also make products more shelf-stable, and the uniform material allows for optimal dosage control.

Other benefits include taste and texture. Homogenized substances feel better on the palette as they’re smooth and uniform. Throughout the world, homogenizers are used in countless products. Their application in the cannabis industry is nothing but the food industry remaining true to form.

GETTING THE RIGHT TOOLS FOR THE TRADE

With an industry as promising as cannabis edibles, commercial cannabis foods and beverages are here to stay. Smart producers will industrialize and make sure that they can keep up with the market and the regulations.

Like every other level of food production in America, the right tools define a corporation’s potential success. Are you looking for specific edible production equipment for your facility? Cannabis Tech Marketplace includes a variety of commercial edible production equipment.